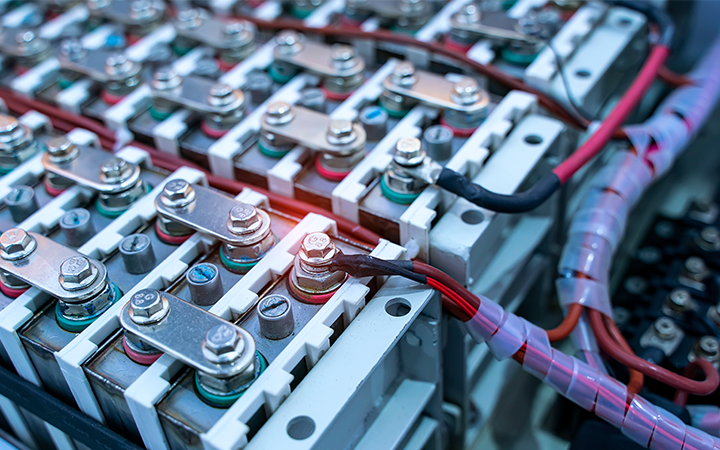

cetecom advanced supports battery and automotive manufacturers in the safety qualification of high performance Li-ion battery systems. The safety of lithium-ion batteries, especially for application in electric vehicles and energy storage systems, is very important. Especially the high energy density due to the chemical elements used as well as the exceptionally high electrical charge must be controlled even in extreme situations to avoid hazards. Our battery safety testing services include a wide array of qualification procedures, which enables us to provide our customers with the necessary certifications for their (Li-ion) batteries.

The expertise and extensive testing capabilities of our battery testing labs ensure that all regulatory requirements are met.

We have various accreditations for environmental and endurance testing and offer a wide variety of tests and test contents:

Since 2003, special rules have been in place to ensure the safe transportation of Li-ion batteries.

These UN transport regulations have been issued by the UN and apply to transport by land, sea and air.

All batteries falling under UN 3480 have to undergo a UN Transport Test UN 38.3.

cetecom advanced verifies the safety of these batteries according to ST-SG-AC.10-11, 38.3.

With a test facility for Abuse Tests on large batteries that is almost unique in Europe,

cetecom advanced has further strengthened its testing capabilities for the automotive industry.

Our Abuse & Safety tests include various test scenarios:

The development of advanced lithium-ion battery packs requires expertise and experience to balance the required system load with the required reliability and safety. cetecom advanced supports assemblers of battery packs in the development of safe battery systems, no matter in which application area.

We offer accredited testing according to the following international standards:

Other standards are possible upon customer request.

ECE regulations generally refer to a set of internationally agreed general technical guidelines for both motor vehicles and their parts and equipment. Both regulations represent uniform rules with respect to battery-powered vehicles.

In its testing center for high performance battery systems, cetecom advanced is able to perform the different test cases:

We also offer propagation tests to prove chapter 6.15. We are designated by the KBA (Kraftfahrt-Bundesamt – German Federal Motor Transport Authority) as a technical service for ECE R100 and ECE R136. In our modern equipped battery test center we perform the described tests for you and support you in the handling of the KBA approval/homologation.